What’s new in the world of brewhouses and brewing technology for craft breweries these days? We sent out a call for brewing equipment manufacturers to tell us. What came back showcases some great small scale, customizable systems purpose built for today’s craft beer industry, as well as some souped-up, automated behemoths for those big and/or adventurous enough to portal into the future.

Gusmer Enterprises, Inc.

mbt Brautechnik brewhouses

This is perfect for: New or Expanding Pub, Pilot and Production Breweries from 1-50 bbl

Mbt Brautechnik offers 1-50 bbl brewhouses in standard or custom configuration from manual 2 vessel systems to fully automated multi-vessel systems (and anything in between) designed to handle any production requirement. Mbt brewhouses are carefully and cleverly engineered to deliver top notch quality and a great value that is 100% Made in Germany. Mbt is also capable of engineering expansion solutions for your existing brewhouse — regardless of whom the original manufacturer was. A broad range of finishes are available: from industrial to showcase in stainless or with copper cladding options available to add a classic feel to your project.

- Flexible engineering: from standard brewhouse designs to complete custom specification

- Complete Brewhouses or Individual Brewing Vessels to Expand Existing Installations

www.gusmerbeer.com | [email protected]

Wort Aeration and/or Oxygenation from DENWEL

This is perfect for: Pub, Pilot and Production Breweries from 2.5bbl to 850 bbl

Adequate wort aeration/oxygenation is a critical element frequently overlooked in the brewery. Having sufficiently aerated/oxygenated wort helps to ensure yeast cell growth and ultimately a robust fermentation, which leads to higher quality, better tasting beer that takes less time to produce. DENWEL offers wort aeration and/or wort oxygenation equipment to fit nearly any size brewery and budget. With a range of sizes to accommodate breweries from ~2.5-850 bbl, configurations to allow the use of sterile air, oxygen or both and 3 levels of automation from manual to fully automatic. DENWEL wort aeration/oxygenation units can be configured to be free-standing or wall-mounted to give flexibility of installation in the brewery. Designed, engineered and built in the Czech Republic, DENWEL offers well thought out equipment of the highest quality while providing an excellent value to brewers.

- Efficient injection of air and/or oxygen into cold wort

- A broad range of available sizes and levels of automation to fit any brewery and budget

- Configurations to allow for use of sterile air, oxygen or both

www.gusmerbeer.com | [email protected]

Spent Grain Removal from Ponndorf

This is perfect for: Pub and Production breweries 10bbl and up

Ponndorf Wet Spent Grains Conveyors offer a safe, clean, efficient and low maintenance solution for the removal of spent grains. Unlike most other spent grain removal systems on the market, the Ponndorf is not a pump; it is a pneumatic conveyor which utilizes compressed air to move the wet spent grains away from the lautertun. The Ponndorf design concept has changed little in the company’s nearly 120 year history and provides a low maintenance alternative to other available systems. Spent grains conveyors are available in a broad range of sizes; from the mobile, plug-and-play PONYfant-for pub breweries, to the Type 100 and Type 150- well suited for the craft breweries, on to the larger scale Types 200 and 250. Engineered, designed and built in Germany, regardless of your brewery’s size Ponndorf has your spent grain removal needs covered.

- Durable, low maintenance wet spent grains conveyors

- Conveyors sized to fit most breweries

- More than 100 years of experience in providing spent grain conveyors to breweries world-wide

www.gusmerbeer.com | [email protected]

Paul Mueller Company

Paul Mueller’s eye-catching serving beer tank system delivers fresher beer and creates a taproom experience that will have customers talking. Plus, they offer nearly unlimited flexibility and customization options, making it the perfect choice for any size location.

The Mueller Brewery is energy efficient and water-saving. The serving tank system simplifies storage, uses compressed air instead of CO2, and even has a recyclable inner bag (where #7 recycling exists). You’ll spend less time cleaning, reduce the use of chemical cleaning agents and avoid disposal issues. And get peace of mind with an automated system that allows you to monitor your operation from anywhere. With dedicated temperature control and air-pressured delivery, their Serving Beverage Tanks boost shelf life, reduce product loss and increase productivity while generating revenue from beer, wine, seltzers, cocktails and more.

If you’re tight on capacity and space, Mueller can help with general contracting capabilities, shop and field tank construction and tank transportation. Coming Soon: Design your dream brewery using our high tech 3-D space planner tool.

paulmueller.com | [email protected]

BrauKon GmbH

BrauKon Brewhouse System

BrauKon brewhouse systems are manufactured in their workshop in Seeon, Germany. With more than 35 qualified Brewmasters and Brewing Engineers BrauKon brings in all expertise for setting up custom-made systems for your individual demand. The unique applications for mashing, lautering and wort boiling are well proven and operated by many of the most successful Craft Breweries in the world. Most of our brewhouse projects are built in batch sizes between 5 hl and 300 hl per brew for brewing up to 12 brews per day.

- BrauKon 50 hl fully automated brewhouse system for ideal wort quality

- Flexible recipe range, e.g. from 10 to 24°P at full batch size

- Optimum energy efficiency and low raw material consumption

BrauControl Automation System

BrauKon BrauControl automation systems are easy to operate and reliable state of the art technology. All software and hardware components are based on internationally acknowledged standards for uncomplicated and reliable maintenance and support. Their automation department offers 24/7 support to our global customers. BrauKon Software Engineers and Brewmasters supply competent support for all questions or demands.

- Fully automated process control system with recipe and batch management

- Easy operation with operator interfaces by our own Brewery Experts

- Easy maintenance by reliable industrial hardware and software components

BrauKon Cellar Systems

BrauKon turn-key brewery systems include a flexible and customized setup for your fermentation and processing area. The fermentation and storage tanks are custom-built in design and dimensions. The connections can be fully hard-piped or handled by integrated hoses. Operations can be designed for manual or fully automated mode. The VitaProp yeast handling systems will ensure professional yeast handling for reliable and consistent top beer quality. The HopGun systems will create individual beer taste by efficient dry hopping and injection of alternative ingredients or spices.

- Customized fermentation and storage plant

- Unique HopGun systems for dry hopping and other ingredient injection

- Fully integrated VitaProp yeast propagation and processing systems

www.braukon.de | [email protected]

Precision Fermentation

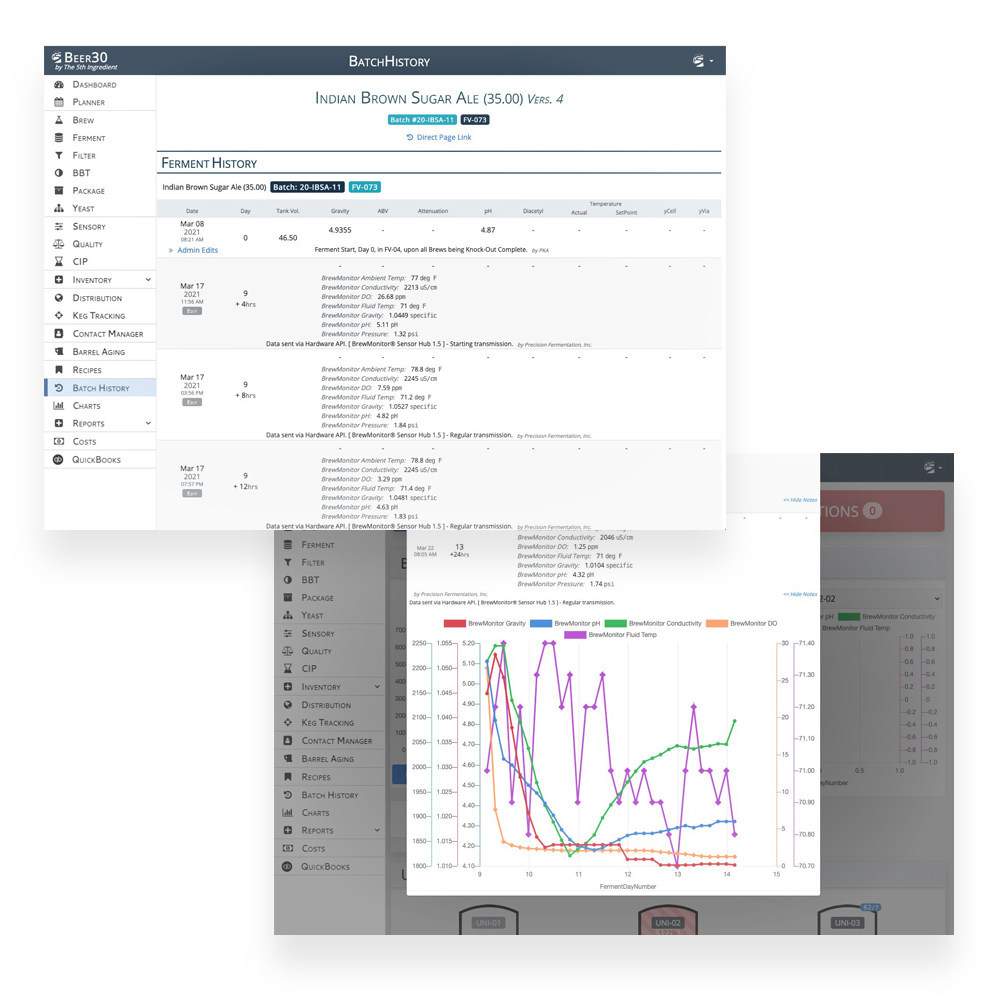

Precision Fermentation, a leading biochemistry technology solutions provider, and The 5th Ingredient, a leading brewery operations management software company, recently announced the first available integration of real-time fermentation data with a brewery operations management system. Through this partnership, BrewMonitor, Precision Fermentation’s flagship Internet of Things (“IoT”) solution, will deliver live fermentation data — dissolved oxygen, pH, gravity, pressure, temperature, and conductivity — directly into The 5th Ingredient’s flagship brewery management software, Beer30.

Automated fermentation data collection enables brewery staff to save time and effort by dramatically reducing the need for manual fermentation sampling and logging. Also, a unified view into both production histories and fermentation outcomes in one interface powers more complete production analyses, helping brewers ensure top beer quality, consistency, and profitability.

GEA

The water consumption of breweries is continuously under scrutiny. Electronic control heads of the of the latest generation enable increasingly simple, error-free setup and operation, as well as advanced functions for process control and monitoring. The modern GEA VARICOVER product recovery systems allow real-time monitoring of the pig position via magnetic sensors. Their mechanical and electronic components form a coordinated unit based on the combination and service-friendly GEA VARIVENT modular system.

In GEA systems, the pig housing is extended in diameter and is equipped with special grippers and springs. The pig is continuously surrounded by the flowing media with a defined range of motion and thus remains hygienically clean. If the pig is subsequently used, a pig catching station awaits it at the end of the pipe section and the return to the sending station. Two valves each control the required inflow and outflow of the motive medium.

The investment in pigging technology can pay off in new construction, but also when retrofitting plants. Christian Blecken enumerates the prerequisites: “It is only important that the pipe section has a constant diameter and does not have any internals so that the pig does not get stuck or lose its sealing effect.”

Festo

MPA-C clean design valve terminals

Perfect for: Every automated brewing system large and small.

In an automated brewing process, pneumatically operated valves automatically open and close to control the flow of fluids, gases, and ingredients. Valve terminals control the opening and closing of these automated valves. No control cabinet is required for the MPA-C, reducing the number of pneumatic lines to and from the control cabinet and thus allowing quicker and simpler installation and rapid access for servicing or maintenance work. Shorter tubing lengths between valve terminal and valves speed up cycle rates for more precise recipe control. On-skid mounting also gives operations greater freedom and flexibility when adding new capabilities as these valve terminals are compact and control cabinet mounting is not required.

- Can be mounted directly on the machine or skid frame.

- It can be located in harsh environments for problem-free cleaning with high pressure jets or foam.

- Made with FDA-compliant materials and is lubricated with NSF-H1 food grade lubricant.

"craft" - Google News

June 21, 2021 at 09:01PM

https://ift.tt/35I03Zu

Craft Brewhouse Showcase 2021: From small-scale systems to full automation - Craft Brewing Business

"craft" - Google News

https://ift.tt/2YrY2MS

Shoes Man Tutorial

Pos News Update

Meme Update

Korean Entertainment News

Japan News Update

Bagikan Berita Ini

0 Response to "Craft Brewhouse Showcase 2021: From small-scale systems to full automation - Craft Brewing Business"

Post a Comment